Project data

Size: 60-bed Care Home

Edmund Williams Architects (Architect), Castleoak Group (Client) and WHS Exterior Render Limited (Sub Contractor)

Products: Knauf AQUAPANEL® Cement Board Outdoor and Knauf AQUAPANEL® Exterior Stainless Steel Screws (SN)

Project details

Early specification of Knauf AQUAPANEL® at the design stage of a 60-bed care home in Winnersh has provided both speed and cost savings for specialist care home developers Castleoak Group.

By utilising the lightweight performance of the Knauf AQUAPANEL® Cement Board Outdoor panels, compared to brick and block construction, designers were able to reduce the size and weight requirements of the foundations.

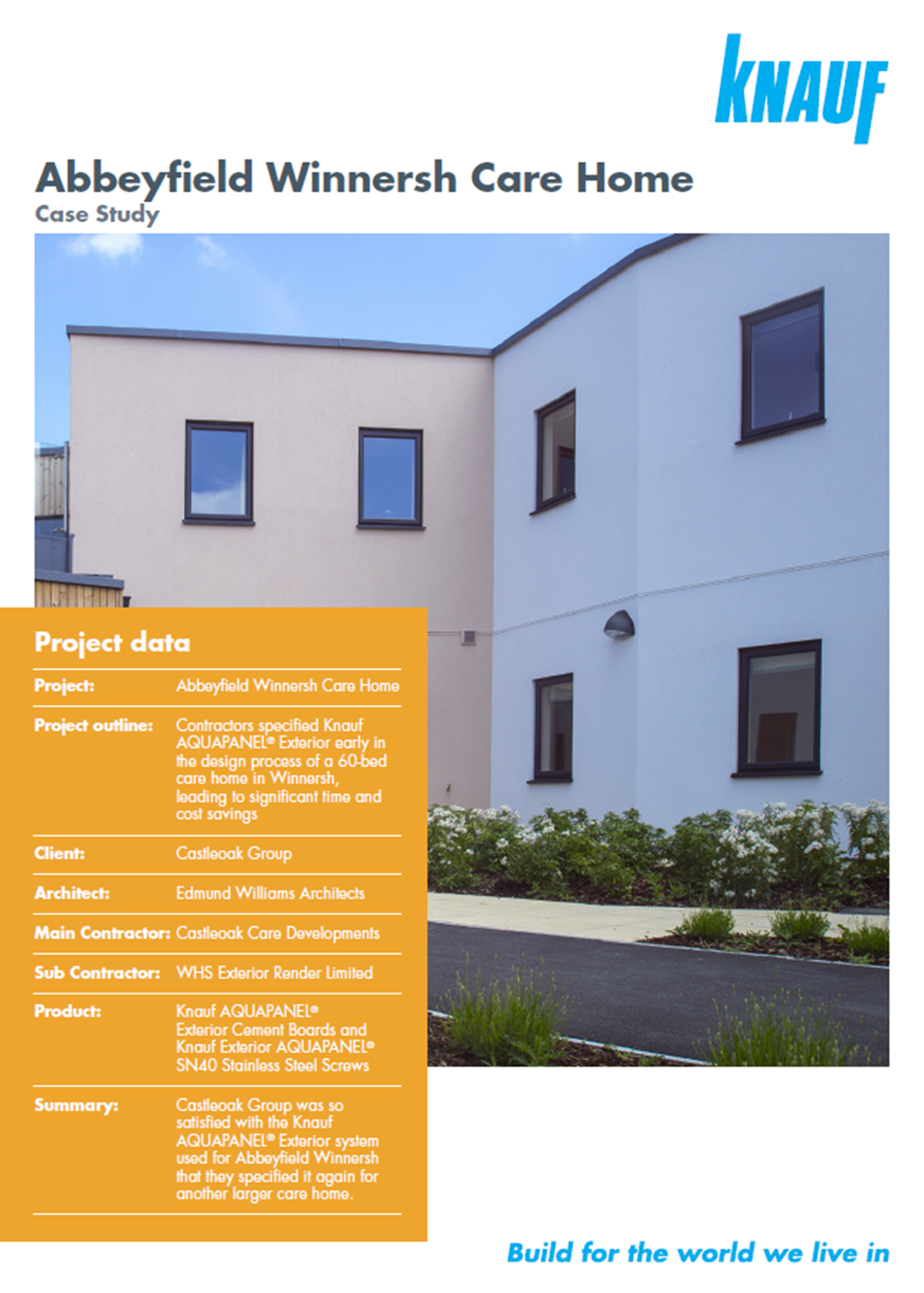

Castleoak turned to Knauf to create an imaginative faceted façade in Winnersh near Wokingham for care operator Abbeyfield. The Abbeyfield Winnersh care home is formed of four striking circular clusters that create a unique community to deliver innovative dementia care. Knauf AQUAPANEL® Cement Board Outdoor was used as a substitute façade system to brick and completed with a rendered finish. Castleoak deployed lean construction techniques to optimise the build process. Work began on site in March 2015 and was completed in April 2016.

Facing cost pressure and difficulty securing brick and block supplies, Castleoak Operations Director Neil Robins and his colleagues were charged with designing a build strategy without the use of brick. “With inhouse timber frame design and manufacturing, Castleoak was able to offer our customer a really innovative build solution”, Neil said.

“The design was challenging, but we weren’t daunted. We knew we had to try something different.”

“Our solution was to prefabricate all panels, floors cassettes, and for the first time, apply external

render panels at the Castleoak factory for this build. This strategy offered a great quality solution – and enabled us to better control the build programme with less dependency on sub contractors.”

The decision to use Knauf AQUAPANEL® was made easier due to its characteristics as a directly applied render carrier board. The cement board combines the benefits of brick and block and, because it consists of aggregated Portland cement with coated glass fibre mesh embedded in the back and front surfaces, provides the ideal key for render.

Knauf AQUAPANEL® was introduced very early in the design stage allowing for further time saving. Knauf’s Specification Team assisted at the design stage where the decision was made to assemble much of the external façade system offsite. The exterior panels were constructed at the Castleoak factory before being delivered to site to be installed by Sequoia Joinery.

Morgan Palmer, Operations Manager at Castleoak was satisfied with the performance of the Knauf products on the Abbeyfield Winnersh project. “The installation of the Knauf AQUAPANEL® panels went to plan. The design and materials were well specified and performed. The programme remained on track.” Knauf AQUAPANEL® Cement Board Outdoor is ideal for offsite installation. Factory fitting, transport and site installation has no adverse effect on its final performance. Rigorously tested and certified by the BBA for use as a ventilated exterior wall panel system on timber frame and steel frame buildings, Knauf AQUAPANEL® Cement Board Outdoor provides a solid, dry base that can withstand the extreme weathering effects of wind, rain and snow. It is also ideal for creating exterior soffits and the illusion of an internal ceiling continuing through the façade to the outside of the building.